Produk

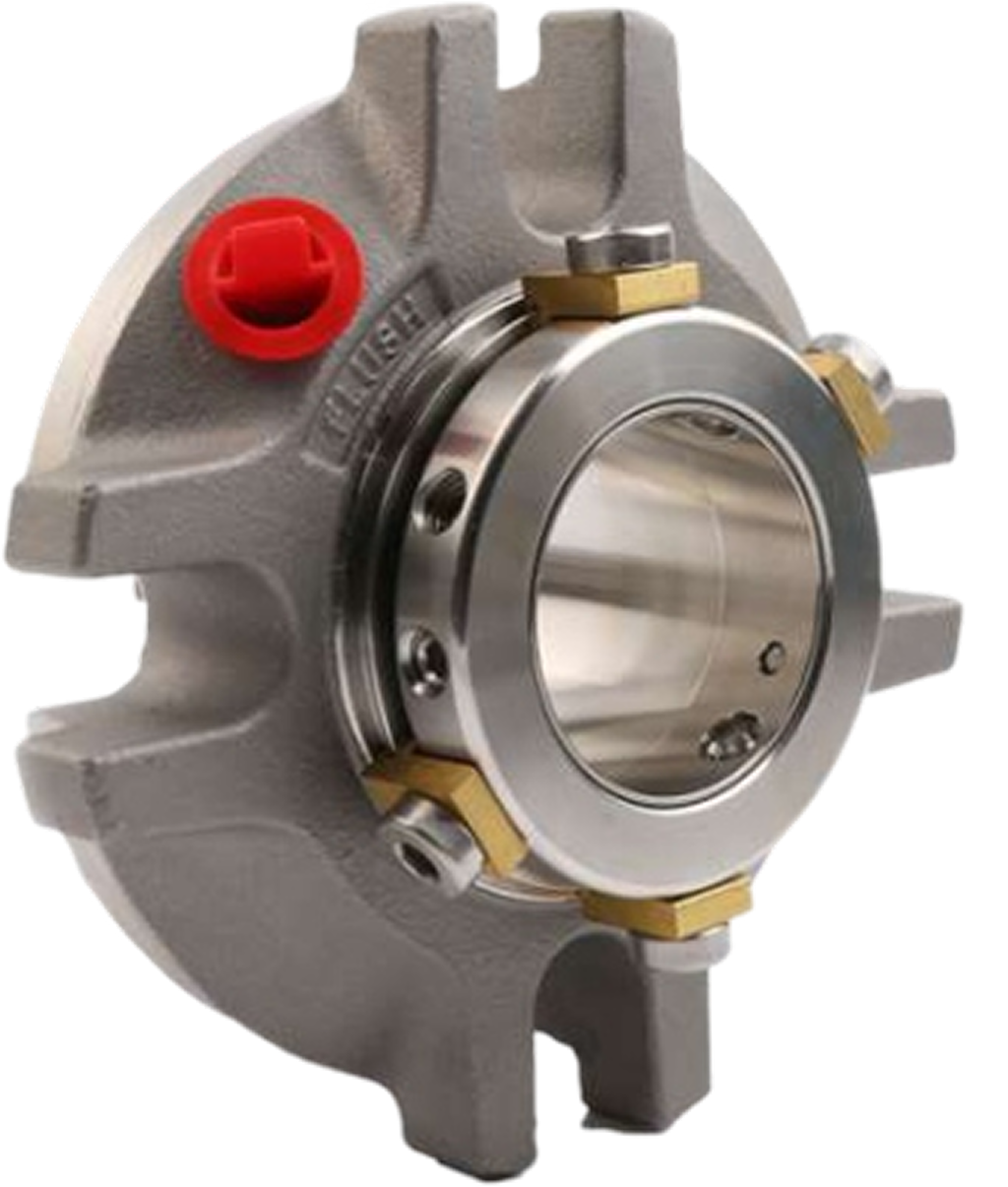

AS - ESM

The Economically Efficient Single Seal Solution for Centrifugal Pumps

316SS/Stainless Steel

- Rotating and balanced design.

- Modular design, universal compatible parts, reduced cost.

- Springs loading protect from liquid, longer seal lifetime.

- Drive screws clamp directly on to shaft or sleeve to minimize drive loss.

- Standard 4 bolts gland designed for ISO 2858.

- Suitable for API Plan 11/21/23.

- Temperature: -20°C~+180°C

- Pressure: 0~20 Bar

- Speed: Up to 20m/s

- Sealing Product: Acid, Alkaline, Low percentage of pulp water, oil, other similar media

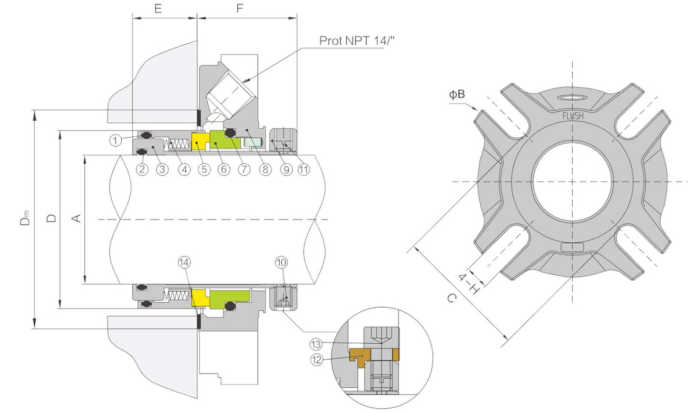

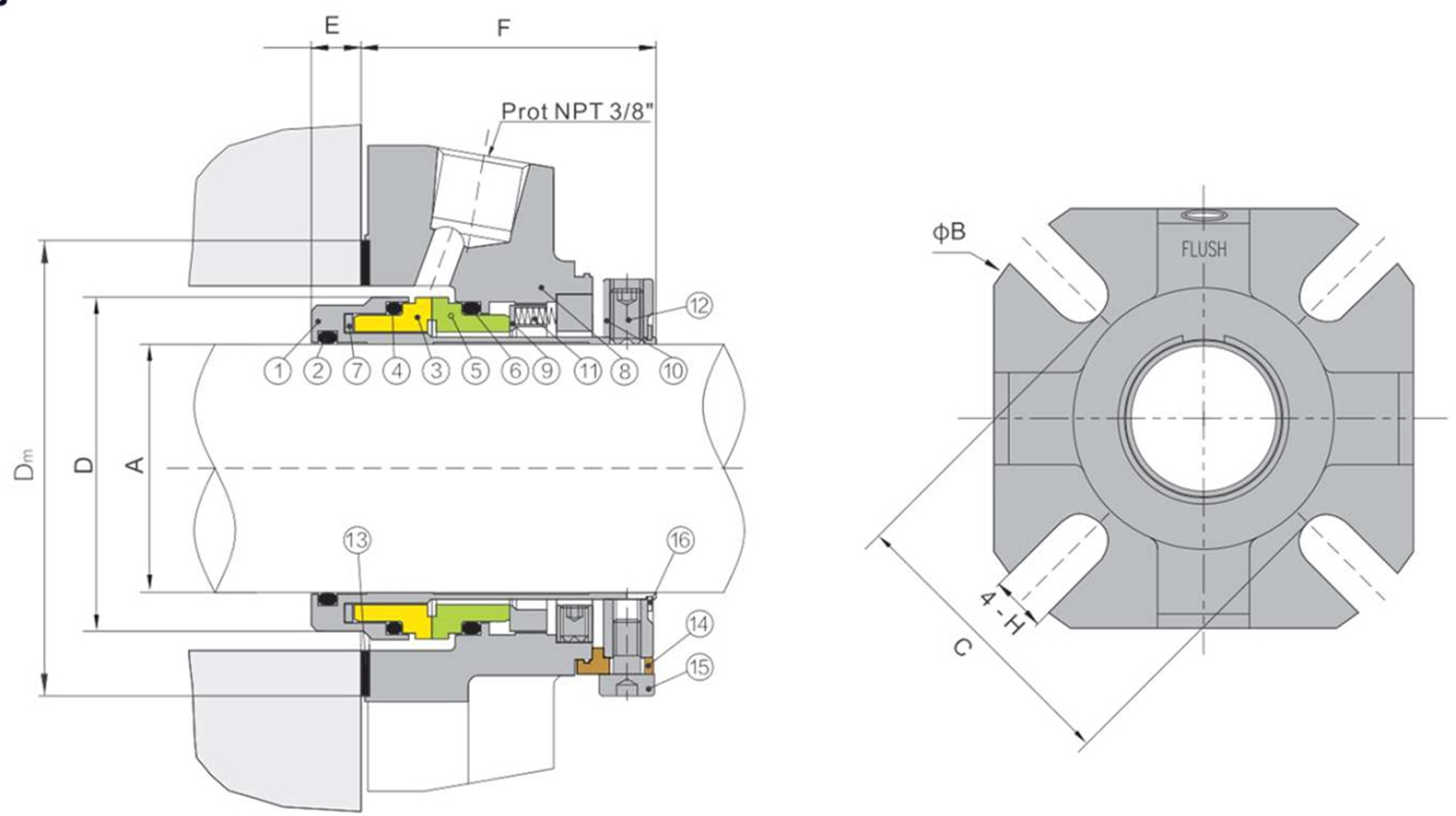

AS - EDM

The Economically Efficient Double Seal Solution for Centrifugal Pumps

- Rotating and balanced design.

- Modular design, universal compatible parts, reduced cost.

- Springs loading protect from liquid, longer seal lifetime.

- Drive screws clamp directly on to shaft or sleeve to minimize drive loss.

- Standard 4 bolts gland designed for ISO 2858.

- Suitable for API Plan 52/53/54.

- Temperature: -20°C~+180°C

- Pressure: 0~20 Bar

- Speed: Up to 20m/s

- Sealing Product: Acid, Alkaline, Low percentage of pulp water, oil, other similar media

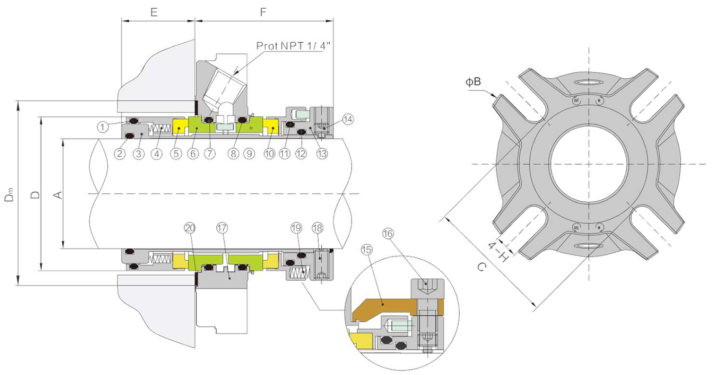

AS - KSC

The Standard Stationary Single Seal Solution for Higher Efficient OEM Customers

- Stationary face compensation technology.

- Solid seal structure reduces deformation at high temperature and low temperature conditions.

- High Speed limits, up to 220 degree. No seal face drop or displacement.

- Higher pressure limits, up to 25 bar.

- Suitable for API Plan 11/21/32/62.

- Temperature: -20°C~+220°C

- Pressure: 0~25 Bar

- Speed: Up to 25m/s

- Sealing Product: Acid, Alkaline, Low percentage of pulp water, oil, other similar media

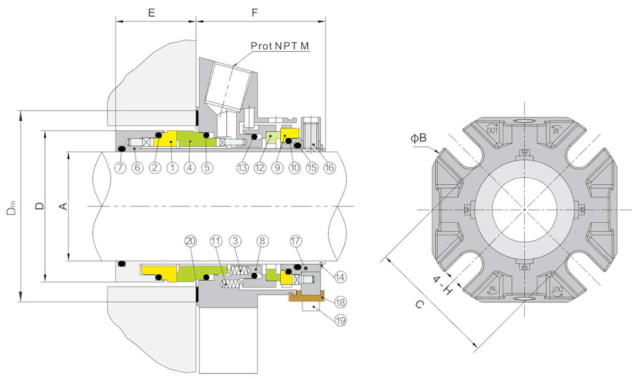

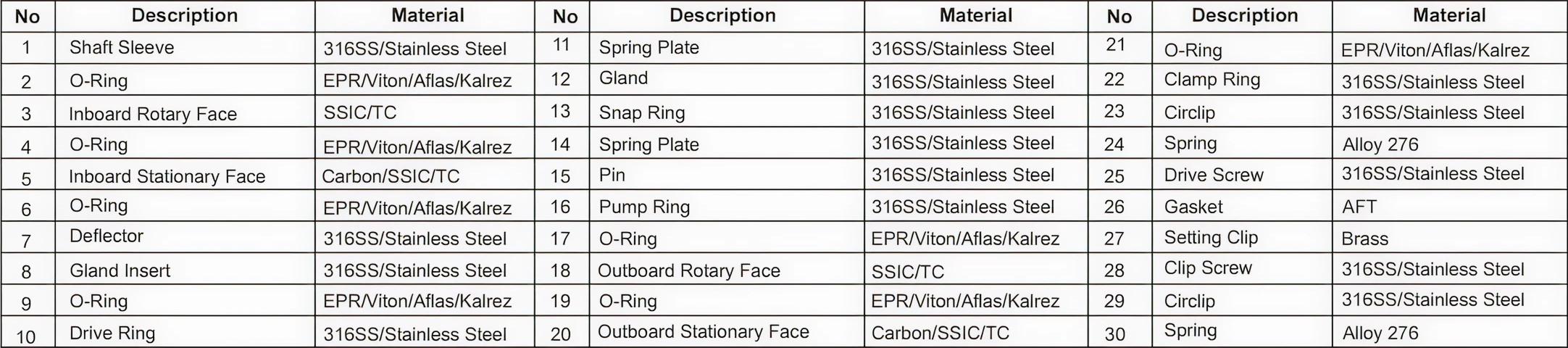

AS - KDC

The Standard Stationary Single Seal Solution for Higher Efficient OEM Customers

Stationary face compensation technology.

Solid seal structure reduces deformation at high temperature and low temperature conditions.

Integrated and Bi-directional diversion, sleeve with pump ring.

High Speed limits, up to 220 degree. No seal face drop or displacement.

Wet part in Duplex steel, 904L, Alloy 276 available.

Suitable for API Plan 52/53A/53B/54.

Temperature: -20°C~+220°C

Pressure: 0~25 Bar

Speed: Up to 25m/s

Sealing Product: Acid, Alkaline, Low percentage of pulp water, oil, other similar media

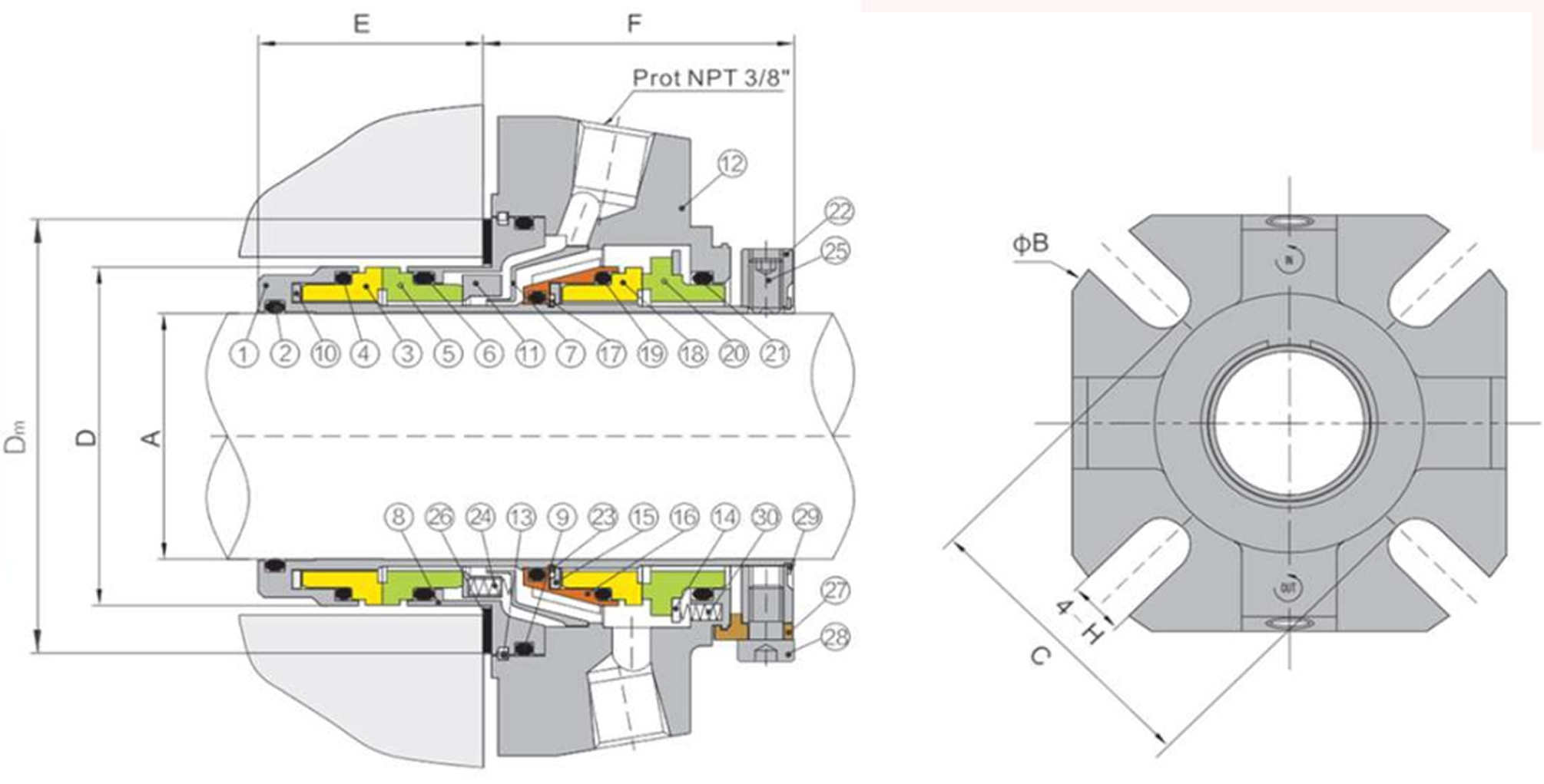

AS - GDM

The Standard Stationary double Seal Solution for Chemical Pump

- Stationary face compensation technology.

- Double balanced solid face design.

- Integrated and Bi-directional diversion, unique pump ring design, excellent barrier fluid circulation.

- High Speed limits, up to 220 degree. No seal face drop or displacement.

- Higher pressure limits, up to 25 bar.

- Wet part in Duplex steel, 904L, Alloy 276 available.

- Suitable for API Plan 52/53A/53B/54.

- Temperature: -20°C~+220°C

- Pressure: 0~25 Bar

- Speed: Up to 25m/s

- Sealing Product: Acid, Alkaline, Low percentage of pulp water, oil, other similar media

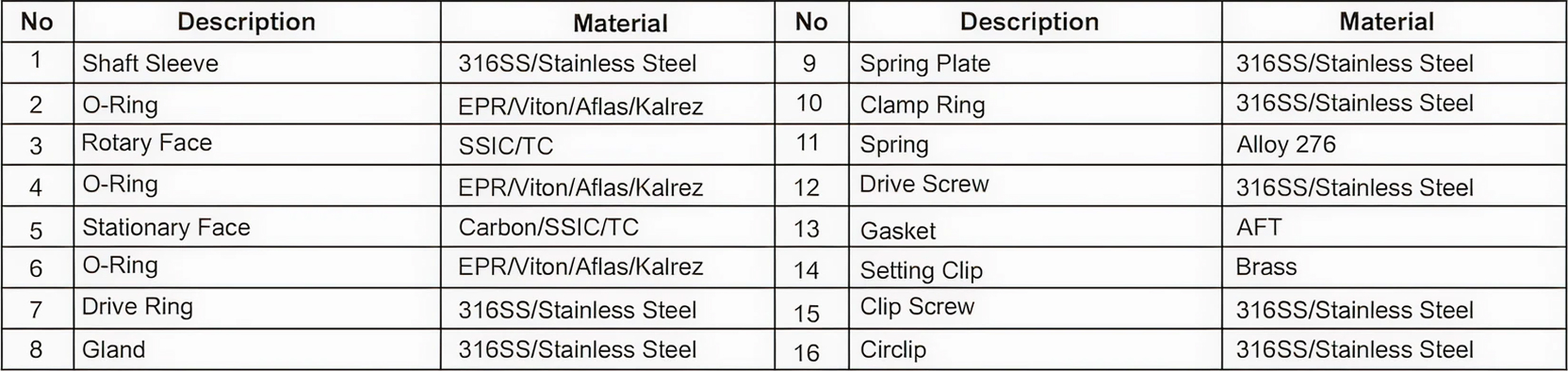

AS - GSM

The Standard Stationary Single Seal Solution for Chemical Pump

- Stationary face compensation technology.

- Solid seal structure reduces deformation at high temperature and low temperature conditions.

- High Speed limit s, up to 220 degree. No seal face drop or displacement.

- Higher pressure limits, up to 25 bar.

- Suitable for API Plan 11/21/32/62.

- Temperature: -40°C~+280°C

- Pressure: 0~25 Bar

- Speed: Up to 25m/s

- Sealing Product: Acid, Alkaline, Low percentage of pulp water, oil, other similar media